The shortage of PPE production during the first COVID-19 wave became tragically apparent in Europe and North America but despite promises made by governments to never allow it to happen again dependence on China continues.

In a report by Sustainable Nonwovens titled ‘PPE shortages: Never again, until next time…’ published yesterday (9th September) experts warn that Europe and the U.S are sleepwalking into another catastrophe as their governments have not improved the production capacity of Personal Protective Equipment (PPE).

According to the report, nearly two years after the COVID-19 pandemic swept across the world and dragged western healthcare systems to their knees “its business as usual”.

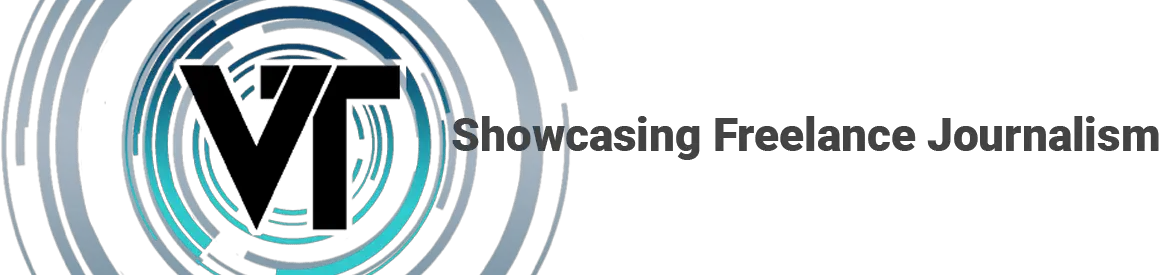

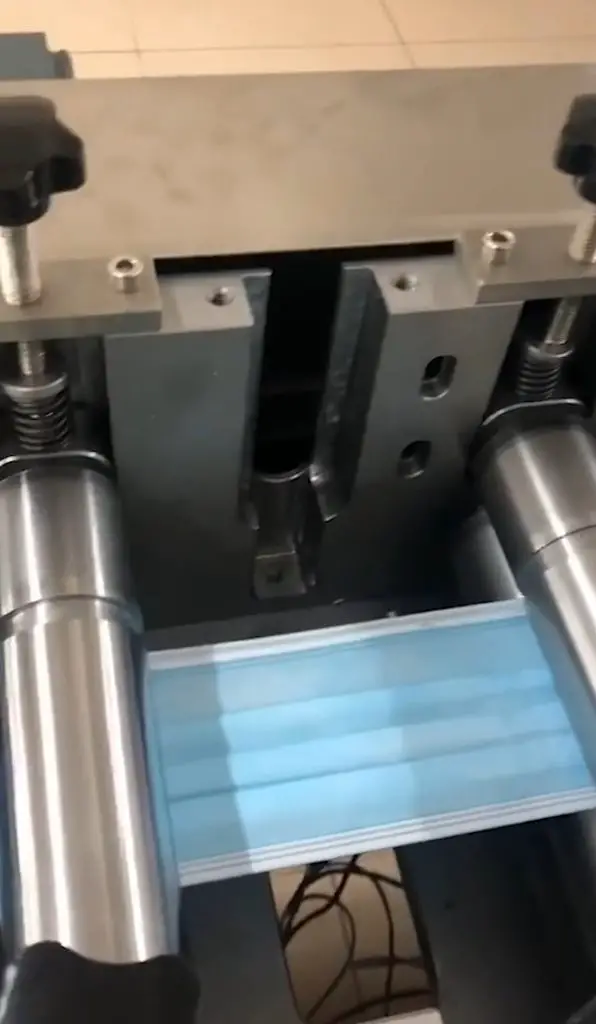

The leading industry report warns that Europe and North America has been flooded with cheap Chinese PPE manufacturing equipment that is not reliable when producing high quantities of face masks, gowns and other vital equipment needed by health care staff during a pandemic.

Carlos Richer, of Diaper Testing International, said: “The cheap Chinese facemask machines which came on the market last year have no stable production rates, result in huge losses of raw material and constantly break down.”

He added: ” If you’re not a skilled mechanic yourself you will most likely be stuck with something that does not work very well, and considering this is a low-margin market, you need to run continuously, without the loss of raw material and without losing time.”

The report details that the key reason for the shortages experienced by Western countries during the height of the pandemic was the unavailability of specialised melt-blown nonwoven filter media.

This type of fabric is key in the production of N95 masks and respirators and its price increased twenty-fold at the height of the pandemic to USD 50,000 (GBP 36,340) per ton.

The Scottish Government responded to the crisis by providing PPE manufacturer Don & Low with a GBP 3.6 million repayable loan towards the GBP 4.5 million purchase of a new meltblown line.

Will Campbell, of Don & Low, said that despite the loan the issue has not been resolved.

He explained: “Sadly, as the UK’s only vertically integrated supplier, we will now stop production because no commitment can be made by the UK government.”

He added: “Most of the UK’s homegrown medical gown and mask manufacturers have now or will soon be stopping production too. China is cheap, stock levels are through the roof and competition laws and rules prohibit institutional buyers from favouring UK manufacturers.”

The situation is not unique to the UK, Norway’s Naukatek AS was founded in March 2020, in direct response to coronavirus with the goal of making the country self-sufficient in producing melt-blown filter material for facemasks.

Liudmila Ilyukhina, the founder of Naukatek AS, claims the company has received little support from the Norwegian government which has already returned to sourcing facemasks from Asia.

Ilyukhina said: “There was a lot of talk by European governments about becoming self-sufficient during the shortages but we have been frustrated by what’s subsequently happened.”

“This was a real opportunity to secure European jobs and knowledge, as well as self-sufficiency in essential PPE, but it hasn’t been taken – even in Germany, where new companies have been heavily subsidised.”

“Sourcing is taking place internationally and is based purely on price. Facemask machines are now being scrapped as a result.”

The European Commission website states: “Economic operators across the EU are working relentlessly to increase their respective manufacturing and distribution capacity.”

It adds: “To mitigate the effects of disruptive factors, they are redesigning their supply chains by launching new manufacturing lines and/or diversifying their supplier base.”

Johan Berlin, from the Swedish machinery consultancy Investkonsult, said: “As long as countries and institutions are restocked and people are vaccinated, then everyone quickly forgets last year’s harsh reality.”

Approximately 129 billion disposable facemasks have been used every month since the start of the pandemic, according to a study in the Journal of Environmental Science and Technology.